Are you pondering over this strange-looking word for quite a while now and wondering what is sublimation printing? Stop doing so. It is nothing complicated but a simple technical procedure that uses a specialized printer to create on-demand apparel.

Sublimation is the favorite technique artists used in the world of crafting. It works with the principle of converting a solid ink into its gaseous state to transfer onto the desired material. After cooling, the ink solidifies again from its gaseous state, leaving a vibrant, bright, and beautiful print on your substrate.

The resulting prints are highly durable and last as long as the object itself. There is a very straightforward series of steps involved in the sublimation printing process. The key to a successful print is using the right paper, ink, and substrate.

Here is our take on what is sublimation printing, how it works, and everything else that one must know before getting started.

How Sublimation Works?

Sublimation printing is commonly known as dye sublimation in the crafting world. For everyone thinking what is sublimation printing used for, it is used to create gorgeous, eye-appealing prints on your desired bases. As mentioned earlier, it refers to the transfer of design from a special paper to a special substrate.

Sublimation changes the form of the print but keeps its essence.

The best thing about this process is the result. It blends all the colors naturally and beautifully into the substrate that doesn’t peel, crack, rub off or even wash away. Unlike other printing techniques, sublimation embeds the ink into the fabric rather than putting a layer.

You can now apply sublimation ink on not only polyester fabric or any object with a polyester coating, but on cotton fabric too. For example, t-shirts, tote bags, mobile cases, pillow covers, ceramic mugs, or those having a polyester coating. It is best suggested to use sublimation blanks which are things coated exclusively for sublimation printing.

Make sure to sure the base is according to the ink you use. For instance, when working with relatively lighter or transparent inks, use light-colored or white bases. Whereas, darker inks would work well on light and dark bases.

What is needed for sublimation printing?

There are a couple of necessary supplies that one requires for thriving results. These include

- Sublimation printer

- Sublimation paper

- Sublimation ink

- Sublimation blanks

- Heat press

- Heat resistant gloves

- Heat tape or adhesive spray

- Lint roller

- Butcher paper

- Design software

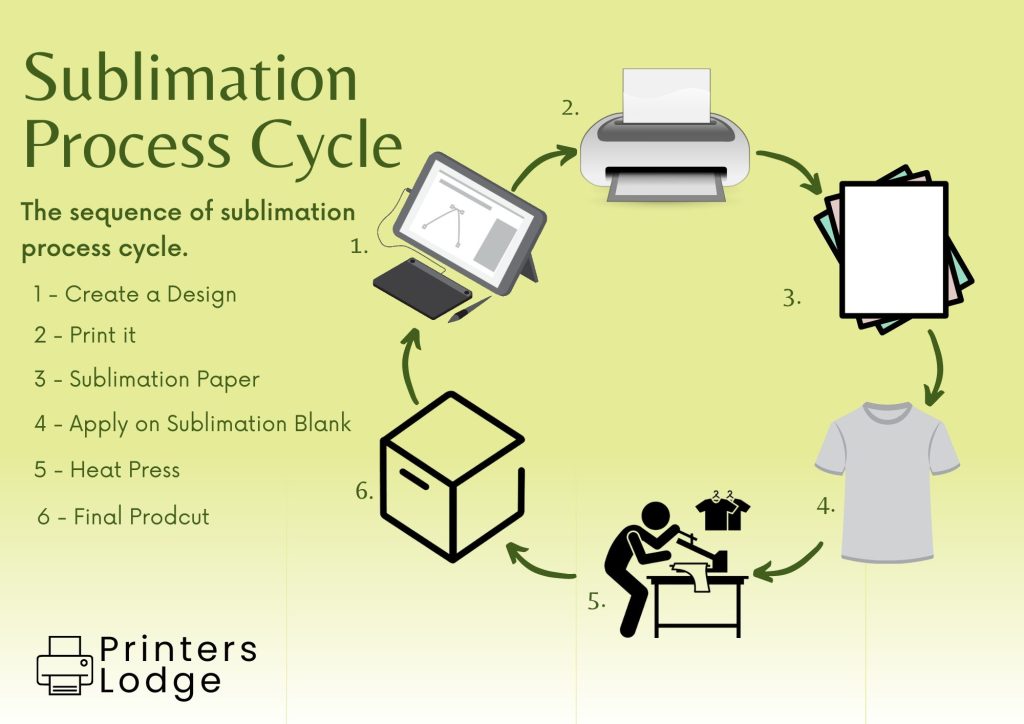

The Process of Sublimation Printing

Once you get your hands on the right supplies, all you need is to carry out the process with due care, steadiness, and lots of patience.

1 – Create A Design

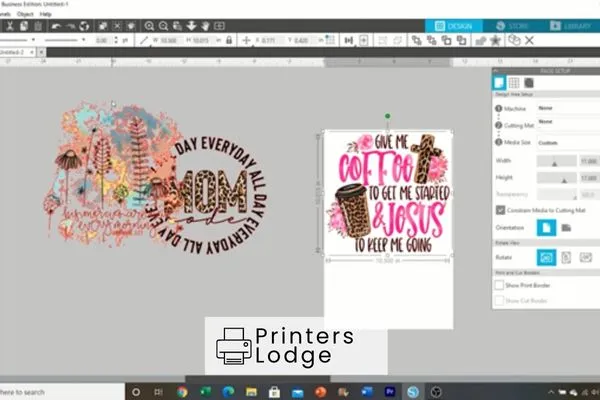

First off, you need to create a design for printing on the desired base. The internet market is flooded with amazing digital designing software that you can use. Professionals usually opt for software like Adobe Illustrator and CorelDraw. Because these are not free, beginners do not prefer these.

Other superb free designing softwares are Silhouette Studio, Canva Inkscape, and GIMP. Whichever application you go for, make sure you make the design per the paper size. It is super important to print the mirror image of your design so that it can be pasted correctly onto the substrate.

2 – Print The Design

Now that you have created a design, take the sublimation paper, place it into the sublimation printer drawer and print out your design.

If it’s your first time, you won’t only be thinking about what is sublimation printing but also how does a sublimation printer work, right?

Well, the printer prints onto the special paper using sublimation ink. In the final step, the crafter transfers this print onto the base.

3 – Transfer Via Heat Press

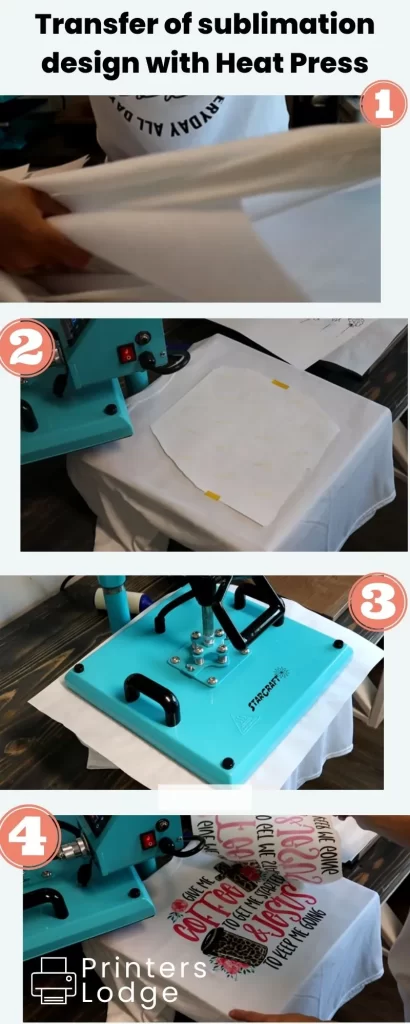

The final step revolves around transferring the design from the paper to the base. For this, you need a heat press machine. Here is how to do it:

First of all, take a piece of butcher paper and slide it between the shirt, or bag that you want to print the design on. This saves the other side of the substrate from absorbing the ink. Butcher papers are the safest choice for sublimation printing because it has no film.

Now take the sheet of your print and tear off the excess paper where there is no print. Turn it upside down and place it on the base. If you are transferring it onto a shirt, it is suggested to place it 3 fingers down from the collar.

The print on sublimation paper would look faded but would be a lot more vibrant after the final heat press. Now, tape down the paper using heat tape so it doesn’t move during the press and prevent the ghosting of colors.

Place butcher paper on top of the paper and press it with the heat press machine. Make sure to not add excessive pressure. Wait for 60 seconds and then move the press.

Remove the butcher paper and gently peel off the sublimation paper from the substrate. You will see a beautifully blended design on the base. As a pro tip, use the lint roller before and after the heat press for cleaner results.

Types Of Heat Press

Depending on the type of printing you perform, here are different types of heat press that you can choose from.

- Small Heat Press: Best suited for small items such as coasters, mugs, handheld kitchenware, etc.

- Calendar Heat Press: Ideal for larger-sized but softer substrates such as banners, signs, etc.

- 3D Vacuum Heat Press: Excellent choice for small objects having various shapes or for things that aren’t flat.

- Flatbed Heat Press: Used best for tougher materials such as glass, plain marble, floor tiles, etc.

Advantages Of Sublimation Printing

- It results in everlasting print without any cracks or peels.

- Works impressively for an unlimited color range.

- Effortlessly create complex designs with high accuracy and vibrancy.

- The ink embeds into the fabric, making it a part of the substrate.

- Highly customizable for designs and colors.

- Gives better results on both lighter/darker bases

Disadvantages Of Sublimation Printing

- Expensive than traditional printing methods because of the materials used

- Could be time-consuming

Frequently Asked Questions

What Is A Sublimation Printer?

It is a machine that specializes in producing enthralling prints using sublimation ink only. Sublimation printers are an advanced alternative to traditional printing with even better results. You can find numerous amazing sublimation printers in the market such as Epson EcoTank, Epson WorkForce, Sawgrass, and more.

What is the difference between regular printing and sublimation printing?

Regular printing refers to transferring the design onto paper using liquid ink. Whereas, sublimation printing is all about permeating the substrate with ink vapors and creating designs.

What can you do with a sublimation printer?

Sublimation printers are highly versatile and can print a wide range of designs including complex ones. These work incredibly well for all colors with high accuracy. You can use these to create appealing designs or graphics and transfer them onto t-shirts, tote bags, mugs, coasters, glassware, or any sublimation blank.

Conclusion

The most widely asked question by crafters is what is sublimation printing? A straightforward answer to this question is, it is a simple process with long-lasting and fascinating results. By using the right supplies such as special sublimation paper, ink, and heat press, you can bring anything from the screen right in front of your eyes on the desired base.